Legislation Guide

This is a guide on Chapter 8 Highways regulations and information on ECE 104

Chapter 8

General Vehicle issues

O5.1.1 Production vehicles are rarely suited to site work in their standard form, so before purchasing a vehicle, consideration should be given to the model‘s suitability for modifications and its ability to carry the necessary equipment. The ease with which an operator can move from the off side seat to the near side door should also be considered.

O5.1.2 The choice of vehicle type, engine size and gearbox should reflect the acceleration and manoeuvrability required of that vehicle during normal working conditions.

O5.1.3 All vehicles and equipment shall be checked for correct operation before work commences. All checks should be documented and all faults reported prior to work commencing. If necessary, the vehicle or equipment should be taken out of service until faults are rectified. Basic vehicle checks should always include fuel, lights, oil, water, electrics and tyres.

O5.1.4 All site vehicles should, where practicable, have

Conspicuity Guide

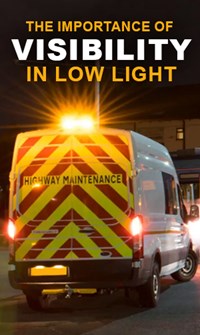

05.2.1 Any vehicle stopping on the highway for works purposes or inspections should be of a conspicuous colour (e.g. yellow or white). A non-reflective yellow is recommended.

05.2.2 Subject to the specific requirements of the following sections, any works vehicles that are used to protect the workforce or form part of the signing of the works should be of conspicuous colour and appropriate marking. This is particularly important for that part of the vehicle visible to drivers and prescribed as part of any sign mounted on the vehicle.

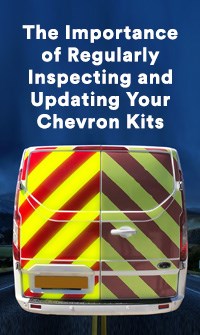

05.2.3 In addition, on high-speed roads all vehicles stopping on the highway for works purposes or inspections shall be equipped with high visibility rear markings. High visibility rear markings should comprise either:

a) Signing to diagram 7403, or

b) The alternative light arrow sign in accordance with section 010.8, or

c) Chevron markings comprising alternate strips of fluorescent orange-red

d) A solid block of fluorescent orange-red

The markings described in ( c ) and ( d ) above should cover as much of the rear-facing portion of the vehicle as possible without obscuring windows, vehicle lighting or registration plates.

05.2.4 Red

05.2.5 Where rear facing high visibility markings may be obscured by any device mounted on the vehicle (e.g. lorry-mounted crash cushion (LMCC) or cone laying adaptation), at any time that the vehicle is stopped on a high-speed road additional markings complying with paragraph 05.2.3 ( c ) or ( d ) shall be applied to any face of the device which is displayed to the rear and other road users.

05.2.6 Works vehicles should be kept clean to maintain conspicuity.

05.2.7 Motor vehicles with a maximum gross weight exceeding 7.5 tonnes and trailers with a maximum gross weight exceeding 3.5 tonnes must be fitted with rear markings in accordance with the Lighting Regulations.

05.2.8 Maintenance vehicles shall be identified by displaying to the rear, the sign to diagram 7404 "HIGHWAY MAINTENANCE". The sign to diagram 7404 variant "MOTORWAY MAINTENANCE" may be used instead when working on motorways only.

05.2.9 Other plant and equipment should be painted in a conspicuous colour.

- Featured

- Bestsellers

- Sale

- Featured

-

3M ECE104 Contour Tape (Rigid Grade) White 50M

From £83.56 - Bestsellers

- Sale

A Tree planted with every order

We have partnered with Ecologi. For every order on our site, we pledge to plant a tree, reinforcing our commitment to sustainability and a greener planet. Visit our forest below.